Portacenter

1 PROCESS, 3 TIMES FASTER

The early robotized machines that replaced the work of humans were the Transfers, which could increase the productivity of individual items or ranges of items. Demand for faster and more flexible changeover then led to the development of CNC Machining Centers.

Neither of the two production models, however, proved sufficiently competitive and companies were in need of new solutions.

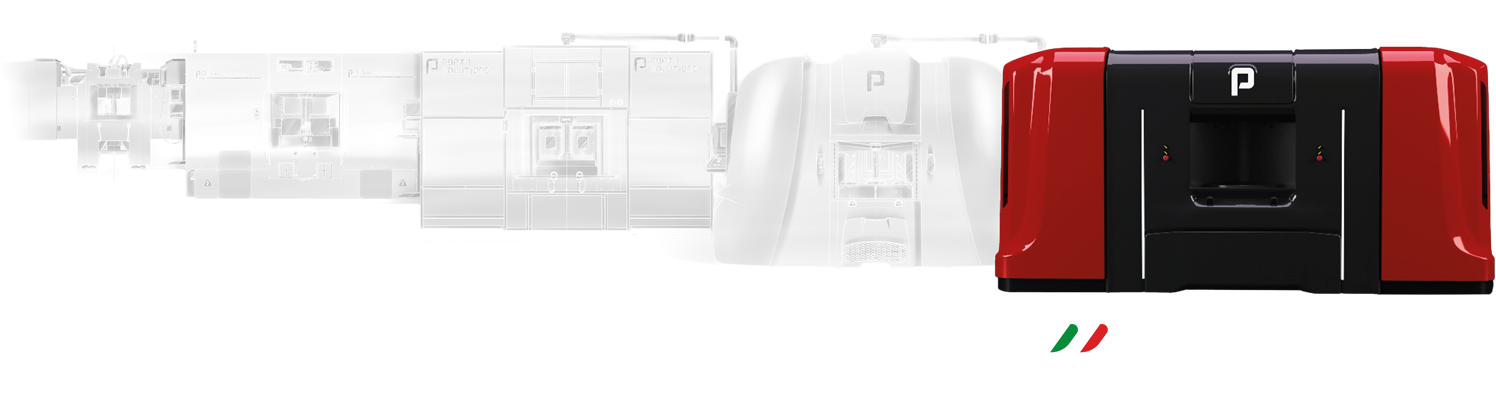

The PORTACENTER was therefore developed: the first Machining Center with 3 independent spindles, 3 times more productive than a single Machining Center and more flexible than a Transfer, perfectly balancing automation and productivity.

Neither of the two production models, however, proved sufficiently competitive and companies were in need of new solutions.

The PORTACENTER was therefore developed: the first Machining Center with 3 independent spindles, 3 times more productive than a single Machining Center and more flexible than a Transfer, perfectly balancing automation and productivity.

To achieve the productivity of a 3-spindle machine you would need to invest in 3 or 4 Machining Centers, which however would involve an increase in costs (energy, human resources, automation) and take up considerably more space.

The PORTACENTER allows to cut the cost per part due to its unique machining process and the 3-independent-spindle system.

The flexibility of this system permits changeover in less than 15 minutes, improving the management of small and medium-sized batches which are in more demand now than ever before.

3 totally independent spindles means that if 1 spindle has to stop for maintenance, you could exclude it from the working module and the machine keeps on producing, at a high rate, with the other 2 spindles.

The PORTACENTER allows to cut the cost per part due to its unique machining process and the 3-independent-spindle system.

The flexibility of this system permits changeover in less than 15 minutes, improving the management of small and medium-sized batches which are in more demand now than ever before.

3 totally independent spindles means that if 1 spindle has to stop for maintenance, you could exclude it from the working module and the machine keeps on producing, at a high rate, with the other 2 spindles.

3-spindle model 250, ISO40/HSK63

CNC Machining Center, synonymous with speed, for those who need to produce quickly and accurately in a 250mm cube.

ENTER

3-spindle model 500, ISO50/HSK100

CNC Machining Center with a 500mm working cube and with great power of removal up to 33 kW at the spindle.

ENTER

Reconditioned PORTACENTERS

Portacenter

START THE CHANGE

Fill in the form below and you will be immediately contacted by our Team, who will talk and work with you to achieve excellent results:

Porta Solutions S.p.A.

Via San Lorenzo, 39

25069 Villa Carcina (Bs)

Tel. +39 030/8172200

E-mail: info@porta-solutions.com

Via San Lorenzo, 39

25069 Villa Carcina (Bs)

Tel. +39 030/8172200

E-mail: info@porta-solutions.com

P.Iva 01966300988

Credits TITANKA! Spa

PLANET PORTA

PLANET PORTA